Isotropic polymer bonded Sm-Fe-N magnets (NITROQUENCH-P)

Sm-Fe-N magnet powders are produced in a similar way to Nd-Fe-B, except that nitrogen is introduced by heat treatment of rapidly quenched Sm-Fe flakes in a nitrogen atmosphere. These flakes are then mixed with a polymer binder and pressed or injected to make isotropic bonded magnets, NITROQUENCH-P.

Magnetic performance of (BH)max=112 kJ/m3 is at the highest level in the world and has excellent corrosion and heat resistance, which opens the door to various new applications.

Features of NITROQUENCH-P

- Material Powder

- Provided by Daido Steel's original manufacturing technique

- Highest magnetic properties among all isotropic bonded magnets

- (BH)max exceeding NdFeB bonded magnets, 98 ~ 112 kJ/m3

- Excellent corrosion resistance

- Possible to use without coating in certain application environment

- Excellent heat resistance

- Thermal coefficient of remanence -0.05 %/deg C ~ -0.07 %/deg C (-20 ~ +120 deg.C.)

- Long-term stability

- Better than NdFeB bonded magnets

- Magnetizing field requirement

- Magnetizing field required for near saturation is 2400 kA/m (30 kOe), which is higher than for NEOQUENCH-P.

Technical support for magnetizing, such as multiple pole magnetization is available on request.

Applications of NITROQUENCH-P

Taking advantage of higher magnetic properties and better corrosion / heat resistance than Nd-Fe-B bonded magnets, NITROQUENCH-P can be used for a variety of applications, such as immersible pumps, cell phones and sensors.

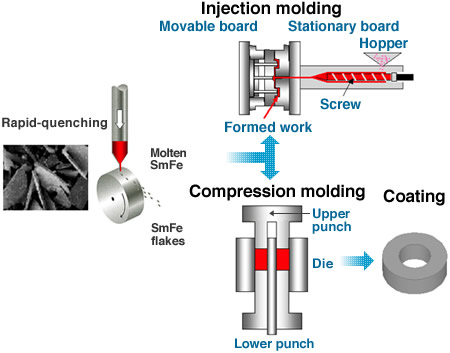

Manufacturing process of NITROQUENCH-P

NITROQUENCH-P is produced by either compression molding or injection molding.

Injection molding

Injection molded magnets are made by injecting the special compound, a mixture of SmFeN magnet powder and high performance polymer, into the mold. These magnets cover a wide range of characteristics as isotropic bonded magents, including heat resistance and higher performance. Injection molding offers very flexible shape design as well as overmolding and insert molding with other parts for easy and reliable assemblies.

Injection mold magnet

Simultaneous molded assembled parts with other part or high end resin part.

Feature of injection mold magnet

- Injection molded magnet has high level of charcteristic as isotropic bonded magnet.

- Since this is isotropic manget, magnetization direction is free to choose, and advantageous for the multipole magnetization.

- Injection molding shows better dimensional accuracy and excellent serial productivity.

- Thin wall thickness minimum 0.3 mm, complicated shape can be produced. *1

- The metal part such as backyoke, hub, shaft or other resin part can be produced with this simultaneous injection mold method.

- Since the resin wraps the manget powder, it is rust proof and can be used by no coating. *2

- 1 There is some case that manufacturing the thickness 0.3 mm could be difficult because of design, please consult with sales staff.

- 2 When the coating is necessary by use condition, appropriate coating for the injection mold is prepared. Please consult with sales staff.

2 Shots technology

2 Shots technology is the method of simultaneous injection molding magnetic powder & resin material together.

Feature of 2 shots injection molding

- Skipping bonding and assembling process

- Improving concentricity

- Decreasing manufacturing cost

Compression magnet

Compression product is made from mixing magnetic powder with resin binder and reaches higher level of performance than injection mold product's.

Compression product

Bond to the shaft or yoke, assembled part set magnet.

Feature of compression product

- As isotropic bonded manget, the highest level of magnetic performance

- Since this is isotropic manget, magnetization direction is free to choose, and advantageous for the multipole magnetization.

- Wall thickness (Minimum 0.3 mm) is available to produce. *1

- An excellent anti-rust performance is realized by the Daido original coating technology.

1 Up to the shape 0.3 mm thickness might be difficult. Please consult with sales staff.